Nio, an electric vehicle (EV) manufacturer, embarks on a groundbreaking endeavor, weaving humanoid robots into its production processes. At the helm of this ambitious project stands Yi Peng, Nio’s Head of Humanoid Robots for Intellectual Engineering, who unveiled detailed insights at the China Humanoid Robot Ecology Conference 2024 in Shanghai.

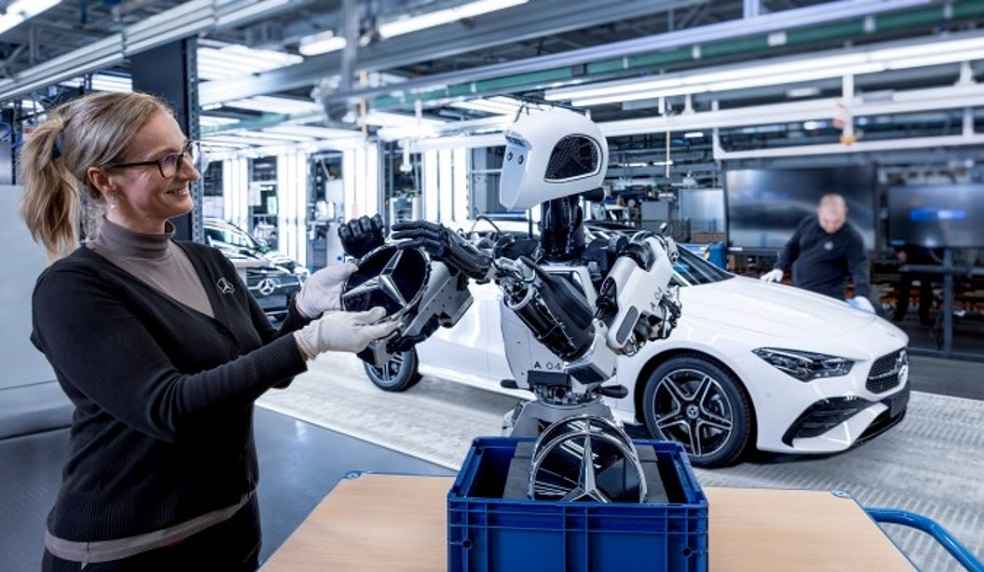

The journey commenced in 2023, marking a pivotal turn in Nio’s approach to manufacturing with the assembly of a specialized humanoid robot ‘squad.’ A collaboration spotlight occurred with UBTech Robotics, a leader in humanoid robotics, demonstrating the Walker S robot’s adeptness in quality inspections within Nio’s factory setting, a testament to the precision and adaptability humanoid robots contribute.

Nio’s manufacturing bases in Hefei, Anhui province—F1 and F2—exemplify automation and efficiency. The incorporation of humanoid robots into these facilities signifies a bold vision for the future of vehicle production. Yi Peng critiques traditional automation’s failure to meet modern manufacturing demands. Humanoid robots, embodying human-like form and intelligence, present a solution, enabling safer, more proficient operations.

Yi Peng articulates the transformative potential of humanoid robots for the industry, stating, “We believe that the scaled application of humanoid robots can facilitate the transformation of the automotive industry towards intelligence, globalization and decarbonization,” This vision transcends immediate practical applications to embrace broader goals of innovation and environmental stewardship.

The pathway toward ubiquitous adoption of humanoid robots in automotive manufacturing is expected to unfold gradually. Yi delineates a tripartite commercialization strategy: scenario-driven, efficiency-driven, cost-driven. The initial phase necessitates identifying pivotal applications, followed by enhancing system operations, and ultimately, achieving cost efficiency at scale.

Applications where humanoid robots could make immediate impacts include logistics, parts assembly, and quality inspection. These roles not only underscore the robots’ versatility but also their capacity to mitigate challenges like escalating labor costs and the necessity to replace hazardous operations.

As Nio forges ahead with the integration of humanoid robots into its production lines, the company’s dedication to pioneering technologies—algorithms, dynamic sensing, and large models—signals a commitment to redefining automotive manufacturing’s boundaries.

Nio’s venture into humanoid robotics is not merely a demonstration of the company’s innovative ethos but also a harbinger of the manufacturing domain’s future, where intelligence, automation, and ecological consciousness merge. As the automotive sector stands on the threshold of a transformative era, Nio’s initiatives offer a compelling preview of the boundless potential of humanoid robotics.

AUTO TECH | Chinese Firm to Manufacture Slovak Flying Cars