Audi is pioneering a next-generation picking process at its Böllinger Höfe facility as part of efforts to advance digitalization in production and logistics under its 360factory vision. In collaboration with the Fraunhofer Heilbronn Research and Innovation Centers, Audi Sport is exploring how artificial intelligence (AI) and robotics can enhance automotive manufacturing, with a focus on optimizing efficiency and reducing employee workload.

The initiative, rooted in the low-volume production of highly customized vehicles like the Audi e-tron GT, targets one of the most complex and labor-intensive operations: the manual picking of vehicle components from logistics containers, commonly referred to as the ‘supermarket’, to supply the assembly line.

Audi Sport, working with Fraunhofer IAO and IPA institutes, began the project with a comprehensive needs analysis. Employees wore smart glasses equipped with infrared cameras to track eye movement and collect data on visual focus and cognitive load. This data helps identify where support is needed most before trialling new technologies, ensuring that solutions are tailored to real-world demands.

Alexander Müller, Head of Logistics at Audi Sport GmbH, emphasized the unique nature of this approach: “By first understanding the cognitive and physical challenges employees face, we can develop technologies that genuinely support their work and improve human-machine interaction on the shop floor.”

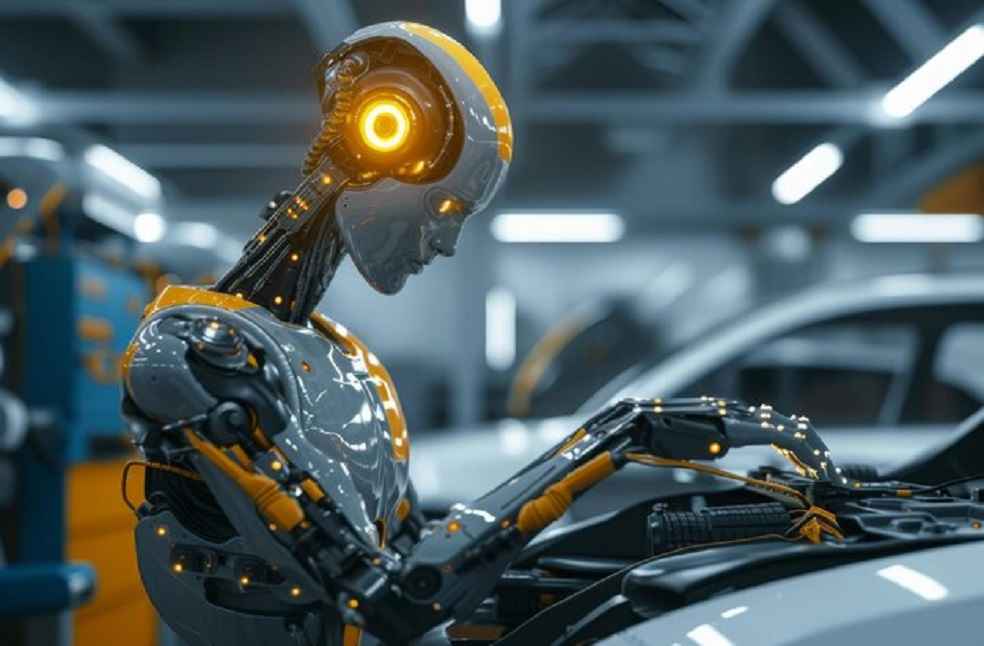

The trials are conducted in a real-world laboratory at the Böllinger Höfe plant, where a replica of the actual picking area enables realistic simulations. Researchers are testing AI applications such as computer vision to assist manual picking and exploring the integration of mobile autonomous robots equipped with advanced sensors and adaptable grippers. These robots are tested using real vehicle orders to evaluate how they can assist or automate parts of the picking process.

Bernd Bienzeisler, Head of the Cognitive Service Systems Research and Innovation Center KODIS at Fraunhofer IAO, described the setup as a milestone in science-industry collaboration. “This is the first time we can evaluate AI, robotics, and sensor-based systems in a real-world production setting with direct input from the workforce,” he noted.

This project is part of the wider Automotive Initiative 2025 (AI25), which Audi launched with Fraunhofer IAO and other partners to drive digital transformation in automotive production. The Böllinger Höfe trials serve as a proving ground for turning research insights into production-ready solutions and are integrated into the broader innovation ecosystem forming around the Innovation Park for Artificial Intelligence (IPAI) in the Heilbronn region.

NEW LAUNCH | Zhengzhou Nissan Launched the Z9, a New Plug-in Pickup Truck